INDEMAK

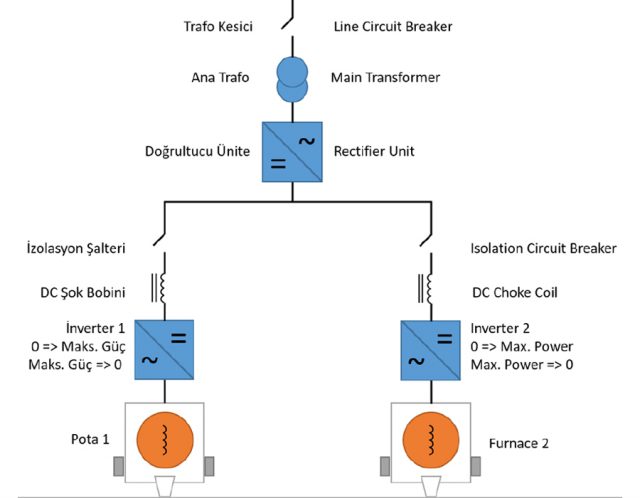

Duet Power® induction melting systems consist of a common rectifier unit that converts AC mains current to DC current and two independent inverter units with same power capability in same cabinet. The general practice is to pour with holding power in the melted furnace, while melting with maximum power in the other furnace. Thanks to 2 separate inverter units with equal power, the maximum power in Duet Power® systems can be shared between 2 melting furnaces with different variations. In addition to the advantages offered by Single Power® systems, Duet Power® systems offer different advantages

• While melting is done with maximum power at one melting furnace, casting can be done with holding power at the other melting furnace.

• Opportunity to save as much time as casting time of a melting furnace

• Opportunity to take hot metal and pour large pieces with 2 melting furnaces due to different power variations

• Possibility to give the desired power to both melting furnaces at the same time without mechanical switch, therefore eliminating the malfunctions that may arise from the mechanical switch

• Possibility of cross-running in case of failure of a melting furnace or inverter thanks to be had a common rectifier and two same power capability inverters.

• Possibility to design 12 or 24 pulses at high power

• Industry 4.0 compatibility with RS232 and RS485 communication

• Advanced control and protection systems

• High electrical efficiency (97%)

• High power factor (≥0.95)

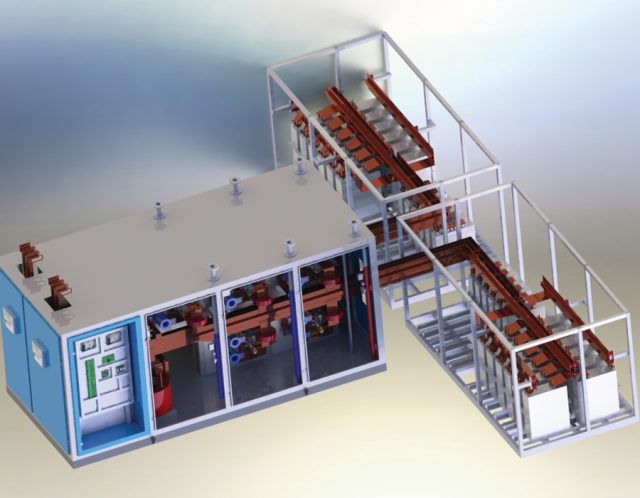

| Model | A | B | C |

|---|---|---|---|

| 350 KW Duet | 3200 | 2000 | 1300 |

| 600 KW Duet | 3200 | 2000 | 1300 |

| 1500 KW Duet | 3800 | 1800 | 1800 |

| 2000 KW Duet | 4200 | 1800 | 1800 |

| 2500 KW Duet | 4200 | 1800 | 1800 |

| 3500 KW Duet | 4800 | 1800 | 1800 |

| 4000 KW Duet | 4800 | 1800 | 1800 |

| 4500 KW Duet | 5200 | 1800 | 1800 |